The constant development of hole joinery is causing increasing expectations regarding the quality of windows and doors, as well as the possibility of making a solid, comfortable fixing of these elements. Due to this, in MS products more than WINDOWS an important role is played not only by functionality, but also by the option of fast and reliable assembly – “fast assembling”. Its implementation is possible m.in. thanks to the new MS mounting anchors.

“Fast assembling” – what is it?

Today’s windows protect the interior from cooling, as wellas transmit the right amount of light to it. Many products also carry out additional tasks, m.in. protects the room from burglary. Due to the fact that the hole joinery is constantly evolving, the functionality of windows is not the only aspect that their buyers pay attention to. Today, the possibility of a decent and at the same time uncomplicated fastening of products also plays an important role. “Fast assembling” is a fast, convenient assembly, carried out with the help of high-quality materials. In MS products more than WINDOWS, the following elements are used for its implementation:

MS mounting anchor – characteristics

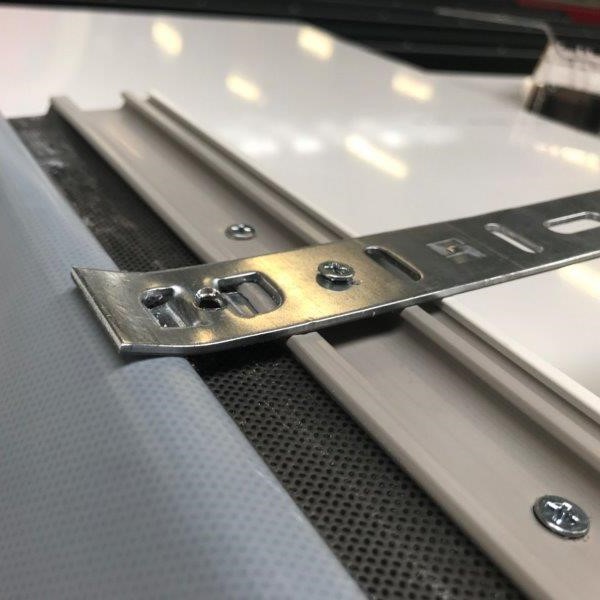

Awareness of the great importance of solid window fixing has contributed to the development of assembly anchors by engineers from MS more than WINDOWS. The author’s MS mounting anchor is 2 mm thick. Thanks to this, the element is characterized by high rigidity and can be used even for large structures. Compared to other components available on the market, the anchor has a longer length of 220 mm. Thanks to it, as well as proper perforation, it is possible to make holes for screws, diffusers and dowels at an appropriate distance from the edge of the masonry. This makes the window can be mounted in such a way that it is extended beyond the wall by 20-25 mm. In order for the anchor to be easily adjusted to the size of the expansion gap between the window and the wall, there are two bean-shaped holes.

Mounting anchor – in which products can it be used?

The proprietary MS anchor can be used when assembling products from the following systems:

MSline+ series windows are made of 82 mm wide unseeded profiles. They come in two versions – AD and MD (without centre seal and with additional middle seal, respectively).

Wood Look products are made of 82 mm wide (MD) non-facing profiles. Thanks to the use of wood-like veneer, they resemble traditional wooden windows. They are created using the technology of welding the corners of the wings and frames at right angles.

ALU LOOK series windows are made using the technology of connecting the corners of frames and wings at right angles. The use of modern veneer makes them look like aluminum windows. These products are made from unseeded profiles with a width of 82 mm (MD version).

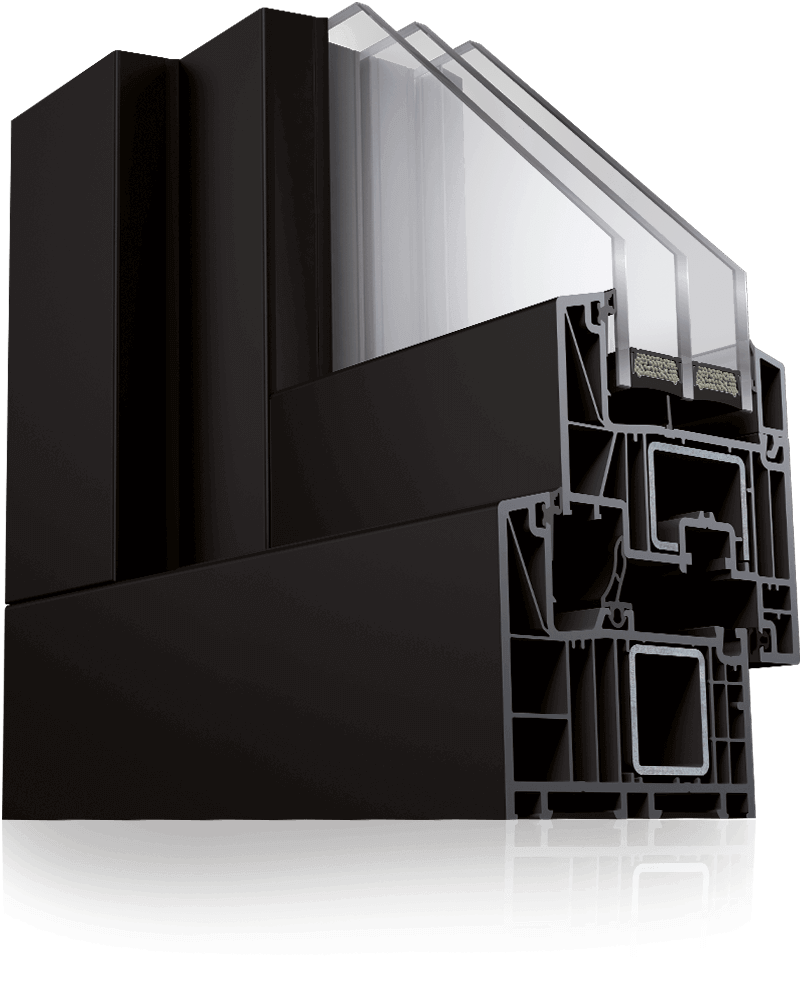

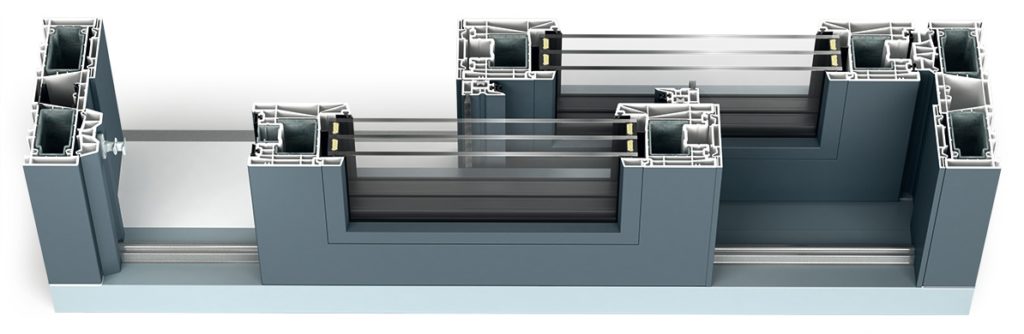

Products from the MS evolution [82] system use 82 mm wide profiles (MD version). They are characterized by a rounded shape.

![Cross-section of the MSevolution window [82].](https://www.ms.pl/wp-content/uploads/profill_soloWEJSCIE_EVO82_W800.png)

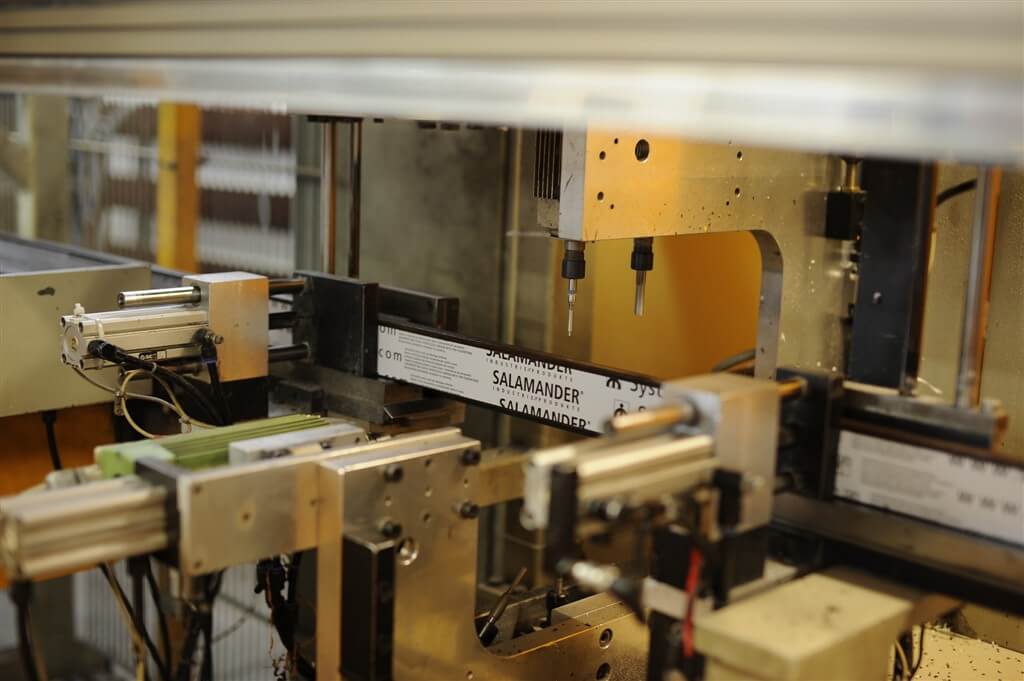

The Patio HST 82 series products are lift and sliding doors. They are made from Salamander profiles using the warm EcoPass threshold. This solution allows you to create large, movable glazing with good thermal parameters.

Openings for mounting screws

To make the installation of windows quick and convenient, i.e. to meet the assumptions of “fast assembling”, MS products more than WINDOW have holes for dowels and mounting screws with the following dimensions:

- 6 mm (hole with a diameter of 6.3 mm),

- 8 mm (hole with a diameter of 8.4 mm),

- 10 mm (hole with a diameter of 10.5 mm).

Thanks to this solution, there is no need to make openings during the installation of windows.