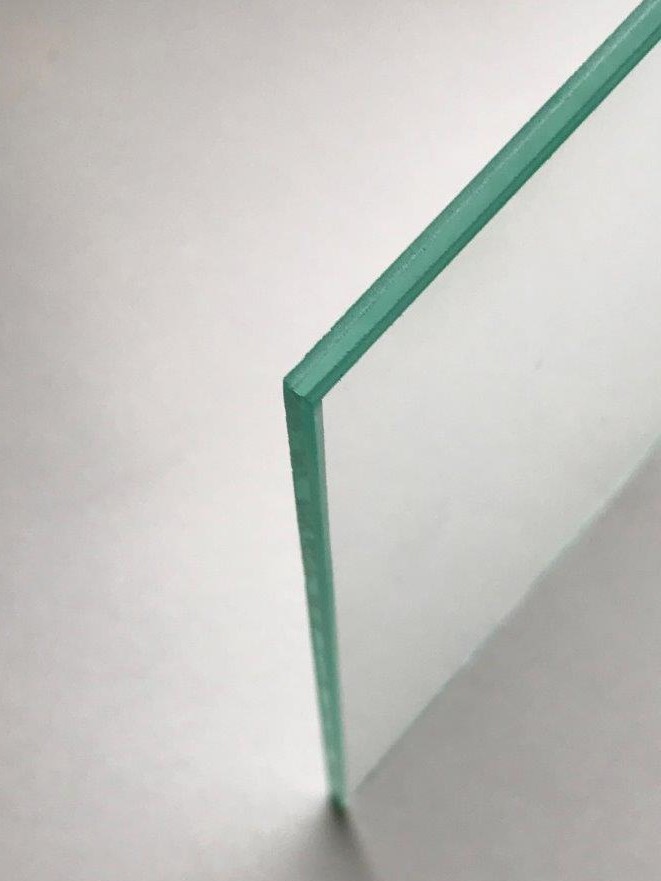

One of the steps in preparing glass panes for windows is cutting them. During this process, sharp edges are created which, among other things, have a detrimental effect on the safety of installers. In order to improve the strength of the panes, as well as to reduce the risk of injury, a special device is used to grind the glass – an arrissing machine.

How are glazed units manufactured?

Glazed units are usually manufactured from float glass. This type of glass is manufactured by pouring heated glass mass onto a flat surface. The mass slowly flows and solidifies to form a smooth surface. The production process is continuous – the molten glass is poured continuously from one side, while on the other side the solidified part of glass is cut off.

Cutting of glass sheets

The finished sheet of glass (JUMBO size 6 x 3.2 m) is delivered to a glass production company. It is then cut into formats to fit the glass to specific window sizes. The cutting of solid glass with machines follows the same principle as in an artisan glassmaker’s workshop. First, the glass pane is scratched with a diamond. It is then broken – a crack forms at the point marked by the diamond.

How are the sharp edges of the panes eliminated?

The method of cutting the glass as presented is associated with the formation of sharp edges. Due to the fact that it is possible to cut yourself by them, it is necessary to remove them. To ensure safety in the further production stages, the edges are blunted by grinding. This is done using an arrissing machine, a special device which is placed at the beginning of the processing line.

Glass grinding – what are the advantages?

The removal of sharp edges undoubtedly has a positive effect on safety during production and window installation. This additionally facilitates the distancing of glazed units. It is worth noting that the removal of the notch on the sharp edge of the glass contributes to the strength of the glazing. This is because their resistance to cracking under various loads – mechanical, thermal and climatic – increases. Although deburring is not a substitute for hardening the glass, it significantly reduces the risk of damage. Thanks to grinding, glazed units are less susceptible to damage during production, transport, assembly and also during use.

Grinded panes in MS beyond WINDOWS

The elimination of sharp edges of glass panes is included in the offer of companies dealing with the production of insulating glazed units. However, it requires additional payment. In the MS beyond WINDOWS factory glass grinding is performed as a standard production stage. Without a doubt, this is unique on the Polish market of window joinery.