Wood is a material with very good physical as well as mechanical properties. It is an excellent heat insulator, withstands significant static and dynamic loads (e.g. in the event of wind pressures). At the same time, it is an ecological material and relatively easy to process. This creates virtually limitless possibilities for making windows and doors, both in shape and in size. Wooden structures are light and very durable. Thanks to the use of laminated wood, as well as pasting additional reinforcements (e.g. glass fibre composites) into the plywood, you can obtain a material resistant to various types of deformations.

Production of wooden structures

Today, woodwork is experiencing its renaissance. Technological development of the wood industry has allowed for a significant increase in the standard of wood products, including window and door joinery. In the production process, only glued laminated wood with an alternating grain pattern is used. It protects them from deformation during changes in humidity and temperature. Thanks to high-quality products for securing wood in the form of impregnations, stains and paints, resistance to external factors, the desired coloration, as well as the depth of natural colour can be obtained.

Production in MS Windows and Doors

Only the highest quality wood is used for the production of windows offered by MS Okna i Drzwi. The scantlings comes only from proven suppliers, and each batch is subject to a detailed inspection. This allows to provide customers with a high-end product that will serve them for years to come. The material used in the products must be properly seasoned, precisely glued together and have the appropriate shape, density and humidity. As one of the few manufacturers of woodwork, we have a system that monitors the humidity of the entire surface of the factory. At each stage of production, the installed humidity sensors regulate the operation of the air humidification system. Thanks to this, the wood maintains the correct humidity throughout the production process. This has a very important impact on the preservation of the proper structure of the raw material, its shrinkage, swelling and strength not only during production, but also during subsequent long years of use of finished products.

Available types of wood

Products from the MS Window and Door offer are made of pine, larch, spruce and oak, as well as exotic wood – meranti or African sapeli mahogany. We are also open to other wood species. Everything to meet customer demands. The available types of wood are as the pictures below.

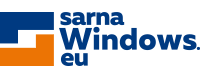

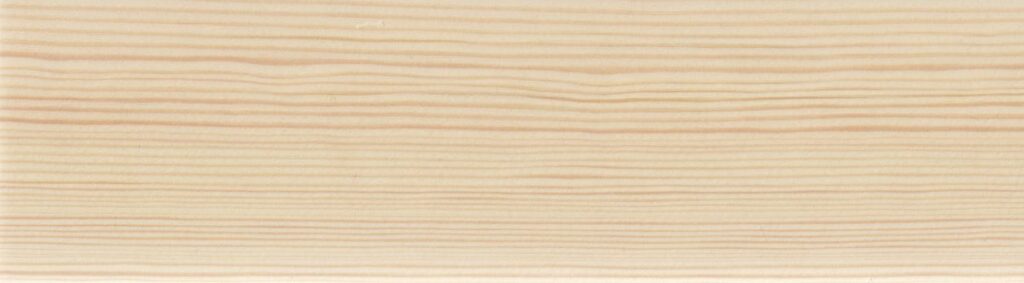

PINE

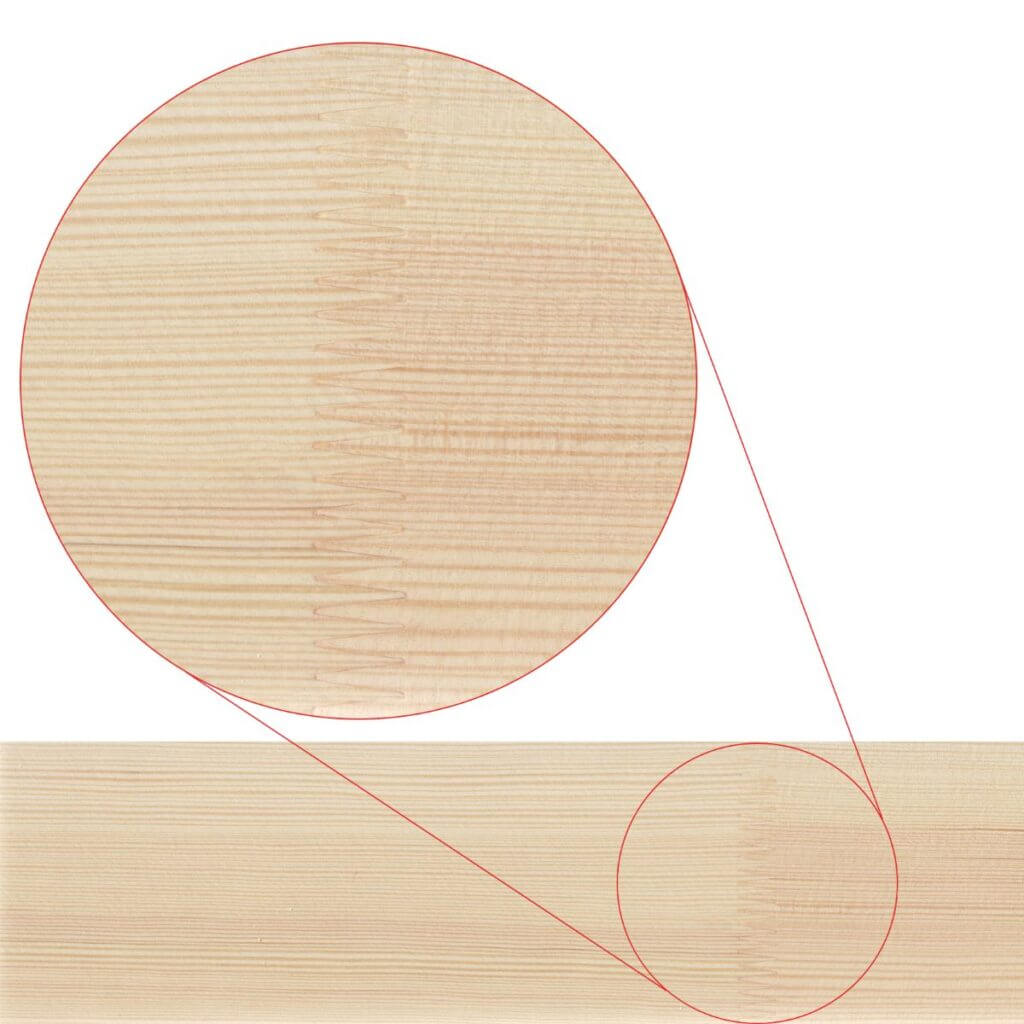

LARCH

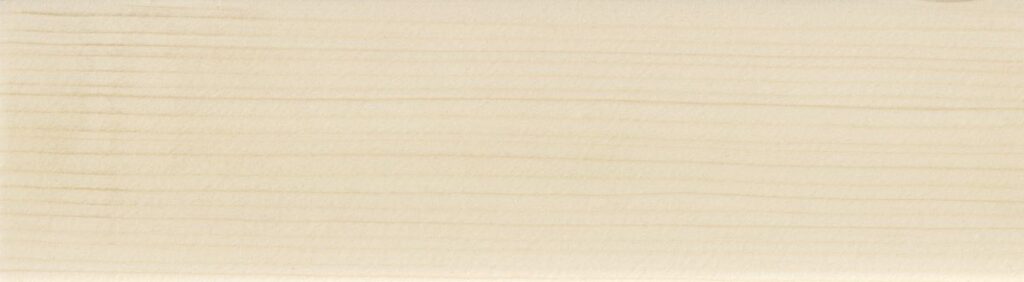

SPRUCE

OAK

MERANTI

AFRICAN SAPELI MAHOGANY

Pine wood is characterized by a bright white and yellow color, which perfectly fits both traditional rustic interior design and gives an unusual atmosphere to rooms with a more austere, modern design. It is distinguished by ease of processing, good mechanical strength and resistance to damage. Provides good thermal and acoustic insulation. Because it has electrostatic properties, it is a material suitable for people who value order and for allergy sufferers. At the same time, being a high-end material, it is also affordable. Pine canteen used for the production of WINDOWS AND DOORS MS, is made by our plant in Osiena. The wood used to produce it comes from the pine kingdom of The Tucholskie Bory. Wood is FSC certified. This means that it comes from a legitimate source and is obtained in a sustainable, non-destructive way of forest management.

The MS Windows and Doors range includes the following options:

- solid pine – used mainly in the production of woodwork covered with azure, i.e. emphasizing the beauty of the wood structure,

- pine combined on mini-trailers – used in the production of woodwork painted with covering varnishes.

Pine specific gravity with optimum humidity (12-15%) 510 kg/m3.

Larch wood looks like pine wood, but its colour is yellowish-red. It is a relatively hard material, quite heavy, and also extremely durable. In addition, it is characterized by resistance to rot in seawater and high fire resistance. Therefore, it is often used in construction. Its advantage is the extraordinary resistance to weather conditions and the action of acids and bases. The high resin content, high wood density and much more difficult processing make it not as popular as pine wood. Siberian larch is used for the production of MS Windows and Doors joinery. In terms of physical and mechanical properties, it slightly exceeds the European larch, but is characterized by a much lighter color.

Specific gravity of larch at optimum humidity (12-15%) 590 kg/m3.

Spruce wood is bright, white in color, sometimes with a shade of bile. It is light, soft and flexible, yet durable and durable. It is easily treated. For its staining, covering varnishes are much more often used than azure. It is not as weather-resistant as other wood species, but it is ideal for use in increasingly popular wood-aluminium joinery. And at the same time it is relatively cheap. It is worth mentioning the interesting properties of this material. With too much load, it starts to crack. In this way, it warns about the threat to the durability of the structure.

Specific gravity of spruce at optimum humidity (12-15%) 470 kg/m3.

Oak is a high-end material, fully deserving of its noble name. Oak wood is hard, heavy and durable. It impresses not only with its interesting structure, but also with the depth of colors, which with age acquire a more expressive, dark shade. Oak is quite easy to process, although it is quite difficult to grind, which only emphasizes its durability and resistance to mechanical damage. In addition, it is also resistant to deformation. This is undoubtedly a material for special tasks. This is mainly due to the resistance to moisture, temperature changes and heavy loads. Suitable care treatments make this wood an ornament of the home for many years.

Oak weight at optimum humidity (12-15%) 690 kg/m3.

Meranti is an exotic wood harvested from south-east Asia. Depending on the place of origin, several varieties of meranti are distinguished, which differ in hardness, density, as well as color. The material comes in shades from pink-brown to burgundy-brown. And the darker its color, the higher the density of the wood. The material is well treated, and thanks to its uniform structure, it perfectly absorbs varnishes and paints. It is often compared with pine wood – because it is a relatively soft raw material. However, this does not change the fact that it comes from the species of toughwoods, whose wood is characterized by low water perihesity. Because of this, it breaks or swells much less often. Compared to pine wood, meranti is also significantly more resistant to mechanical damage as well as to all weather conditions.

Meranti specific gravity with optimum humidity (12-15%) 500 kg/m3.

Sapeli is the common name for a species of wood derived from mahogany trees found in west and central Africa. Like oak, mahogany is a noble species of wood. It is distinguished by an interesting structure – wide, straight stripes – and a unique color, which under the influence of time and external conditions from pink turns into deep red and brown. Sapeli is hardwood, stable, with good mechanical characteristics, especially in terms of susceptibility to compression or crushing, as well as high resistance to external factors. Interestingly, fresh wood has an intense lemon scent, which unfortunately fades over time. This is premium material. Therefore, when ordering joinery from sapels, it should be reckoned with the fact that their cost can turn out to be quite significant.

Specific gravity of mahogany with optimum humidity (12-15%) 650 kg/m3.

Colour variants

Wood is a material with a beautiful and complex structure. Each of the species that have been used in joinery is characterized by a unique colour and graining. Properly selected coating allows not only to emphasize the unique character of wooden products, but also to protect them from destruction. For those who appreciate the natural beauty of this raw material, we offer a rich palette of transparent varnishes, so-called azures. Thanks to them, you can give the wooden joinery an unusual depth of colour, and at the same time preserve its “natural” appearance.

- For lovers of classics, staining from the palette presented below will be a good option. It is worth paying attention to how, depending on the species of wood, the intensity of a given coloration changes.

PINE

MERANTI

OAK

- For those who are enthusiastic about bold combinations of tradition and modernity, the offer also includes tints from the Never Ending Impressions palette presented below. Pine wood is used in the templet, but the colours are available on any other wood species.

- A novelty in the assortment are metallic colours, which are gaining increasing popularity among those who want to combine industrial design with the unique properties of woodwork. Pine wood is used in the templet, but the colours are available on any other wood species.

- Meeting the expectations of customers who dream of an organic product, and at the same time want to ensure a certain neutrality of the design of their interiors, will provide woodwork in covering coatings. RAL colours are available, as well as NCS and Farrow & Ball pallets.

The above pallets are not limitation. To meet the expectations of customers, MS Windows and Doors specialists are ready to make joinery in the chosen colour. An experienced team, in cooperation with the best specialists in the paint industry, will gladly undertake the task of choosing the right recipe.

In order for the joinery to perform its function for many years, MS Windows and Doors uses a four-layer system of high-quality coatings.

1. The first stage is the impregnation of wood.

This process involves saturated wood (up to a depth of 4 mm) by pouring a special product which protects the joinery from the bad influence of various physical as well as biological factors.

- Thanks to impregnation, wood acquires biological resistance, is less susceptible to mold, blue stain or fungi.

- This process reduces the absorbency of the wood, which facilitates uniform staining and stabilizes the material.

- The impregnation allows you to extend the life of the coating and supports colour equalization.

For this process to fulfill its task, the impregnation must be applied at the appropriate concentration. For this purpose, it is inspected by a moisture analyzer method.

2. The impregnated wood is sanded and then layer of varnish called primer is applied by the pouring method.

- The backing layer is selected for the final color of the joinery.

- Its main role is to ensure optimal adhesion of the next layer of the paint system.

- Fills the porous structure of wood.

- Protects against UV radiation, which is responsible for discoloration of the joinery.

- Contains insulating substances that minimize yellowing of coniferous wood with a high content of heartwood.

- Reduces discoloration of the topcoat caused by tannins found in hardwood.

Also at this stage the varnish is subject to inspection. Its appropriate viscosity is ensured by testing with a Ford cup. This is extremely important because the correct viscosity parameter is responsible for obtaining the correct coating thickness.

3. The next step is the application of the so-called interlayer.

- Applied by spraying method, it perfectly protects the areas most vulnerable to atmospheric factors – cross-sections of wood and so-called v-grooves.

- It thoroughly fills the porous structures of hardwood, which increases its resistance and improves the structure of the surface.

- As a vapour permeable coating, it allows moisture to be drained freely from the joinery, which prevents the wood from warping and rotting.

- Increases the resistance of joinery to the influence of atmospheric factors and microdamaging.

- First of all, it minimizes yellowing of coniferous wood with a high content of hardwood.

- Reduces discoloration of the topcoat caused by tannins found in hardwood.

In order to perform its role, the joinery must be covered with an appropriate thickness of the interlayer. This parameter is measured using the so-called ‘measuring comb’.

4. The final stage is the spray application of the topcoat.

- It gives the joinery a good colour, ensuring high transparency of the glaze and high opacity of opacity colors.

- It is characterized by a smooth and even surface, which greatly facilitates the daily use and care of joinery.

- In combination with the previous layers, it forms a hard but flexible coating that is extremely resistant to extreme weather conditions, such as hail or other mechanical microdamages.

- The pigments contained in the final layer provide an effective barrier for UV rays, so that for many years we can enjoy the joinery in a color that does not yellow and does not fade.

The entire wood protection process is subject to ongoing application and product quality control. A grip check of the lacquer layer by means of a mesh of notches (DIN EN ISO 2409 standard) is also carried out.

Care of wooden joinery

The coatings used are water-based, which means they are friendly to the environment and users. In addition, a small container of varnish is attached to each order. It allows you to remove small damage during installation or during random situations. MS Windows and Doors also offers special preparations for the care and maintenance of woodwork, which guarantee satisfaction with the functioning of the structure for many years.

Attention. Photos presenting the offered goods are for reference only. The actual appearance, including in particular the colour and structure of the material, may differ from that presented in the photos.